2016 Can Am Spyder ST

Install By:

Matt Schaeffer

Safe & Sound Mobile Electronics

14508B Lee Rd.

Chantilly, VA 20151

(703)631-4104

www.mysafeandsound.com

View: Safe & Sound Inc.

Products Used:

- Focal 130KR Speakers

- Focal SUBP25F Flax Subwoofer

- Mosconi 100.4 DSP

- Mosconi MOS-BTS

MORE BY THIS INSTALLER:

Notes

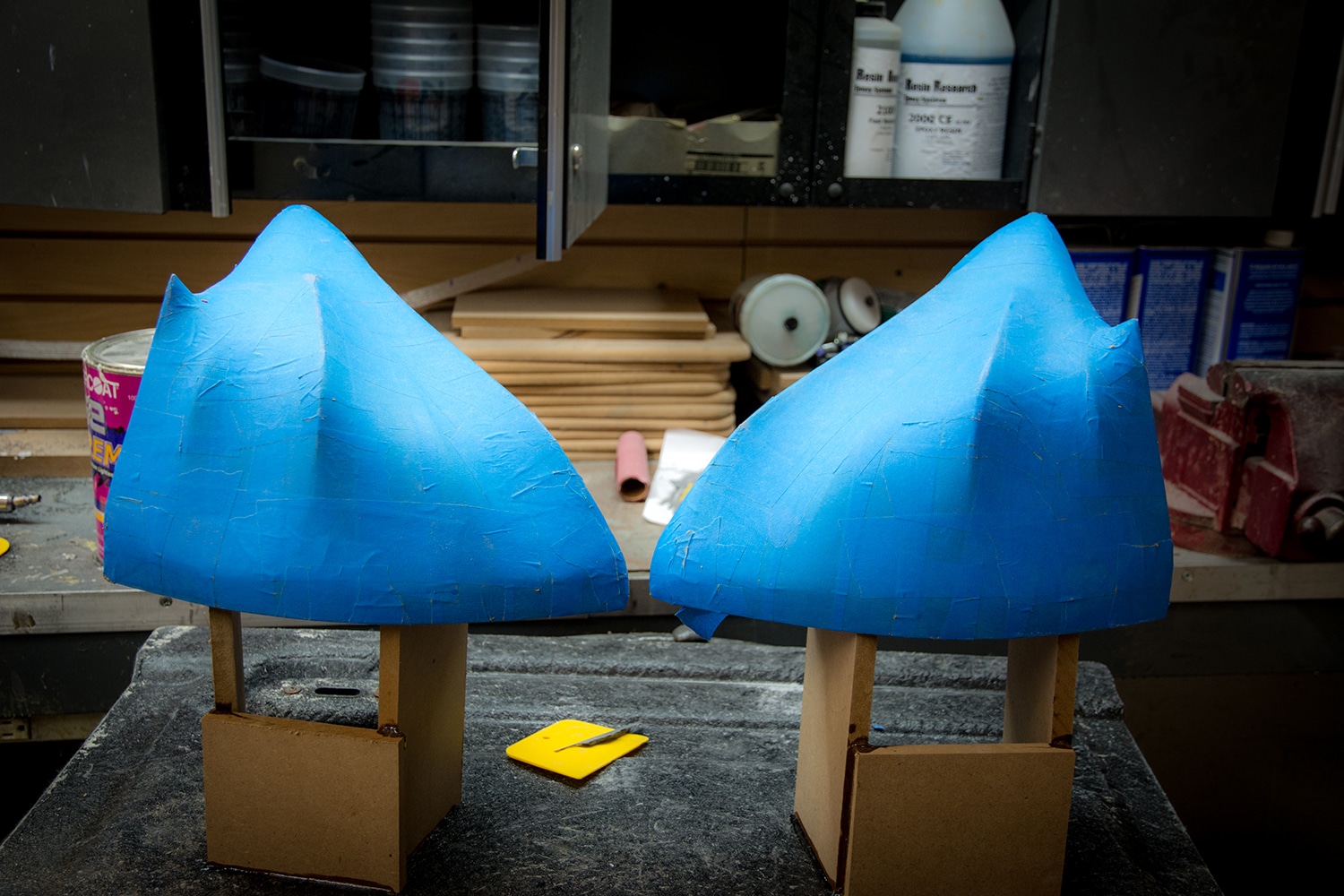

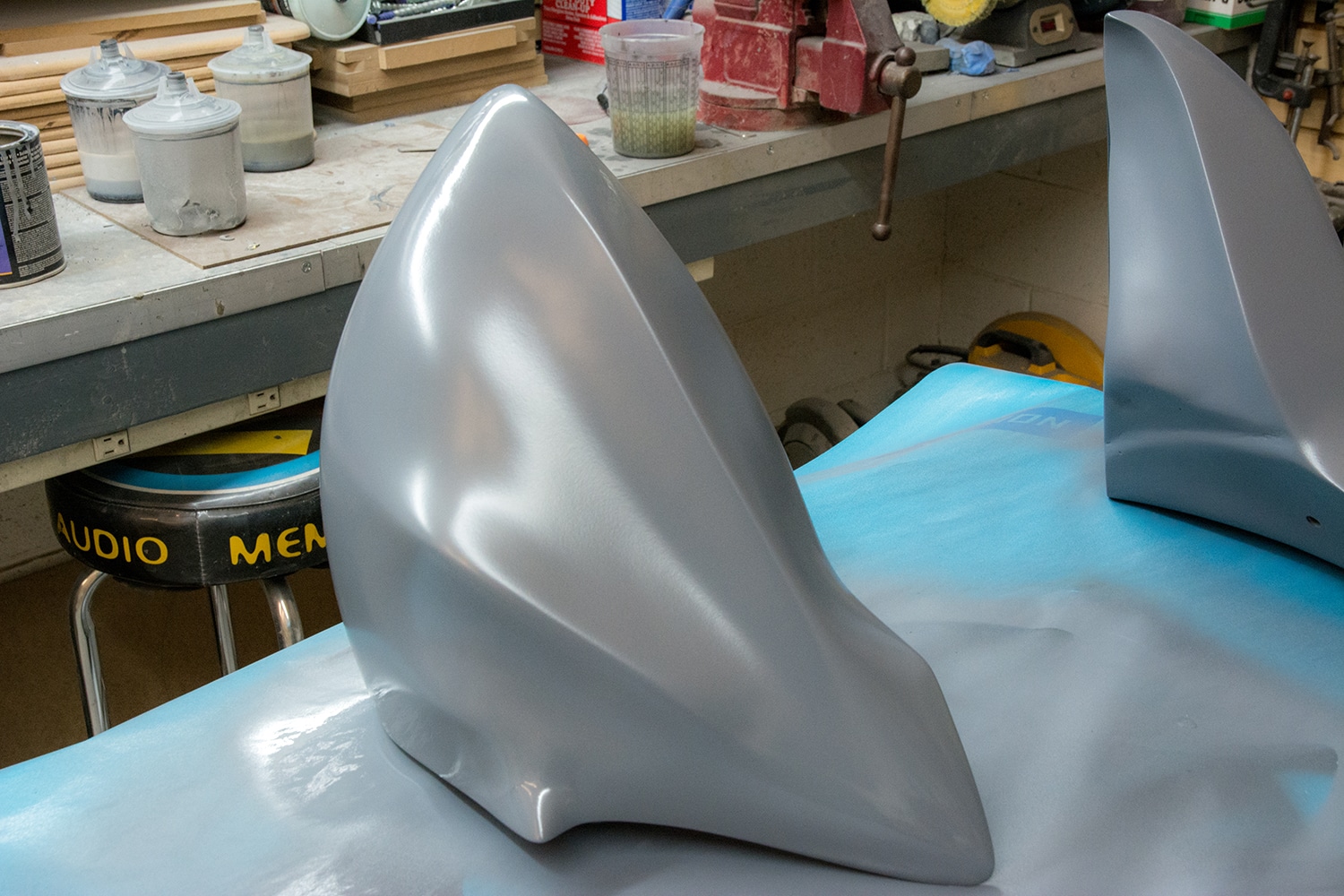

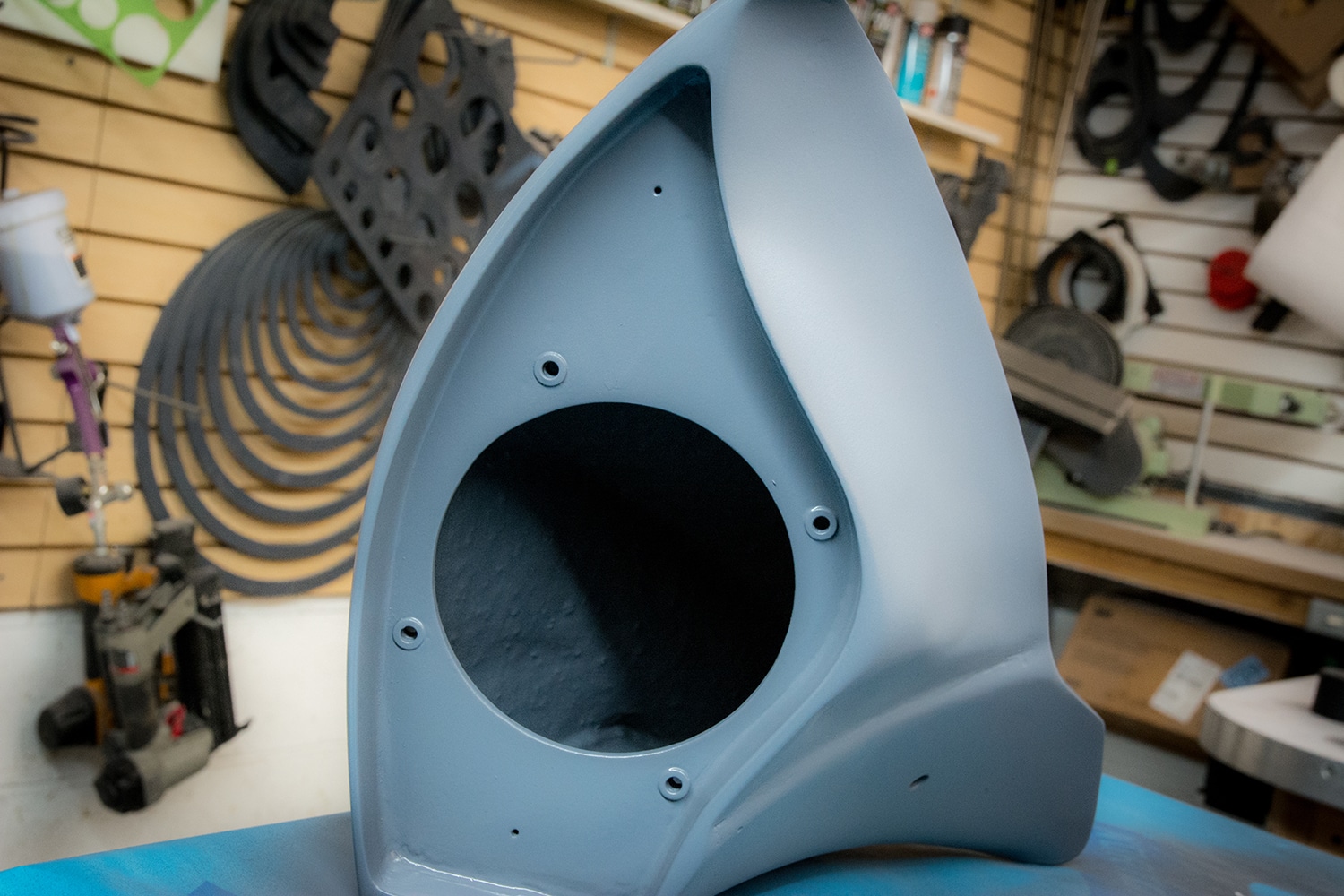

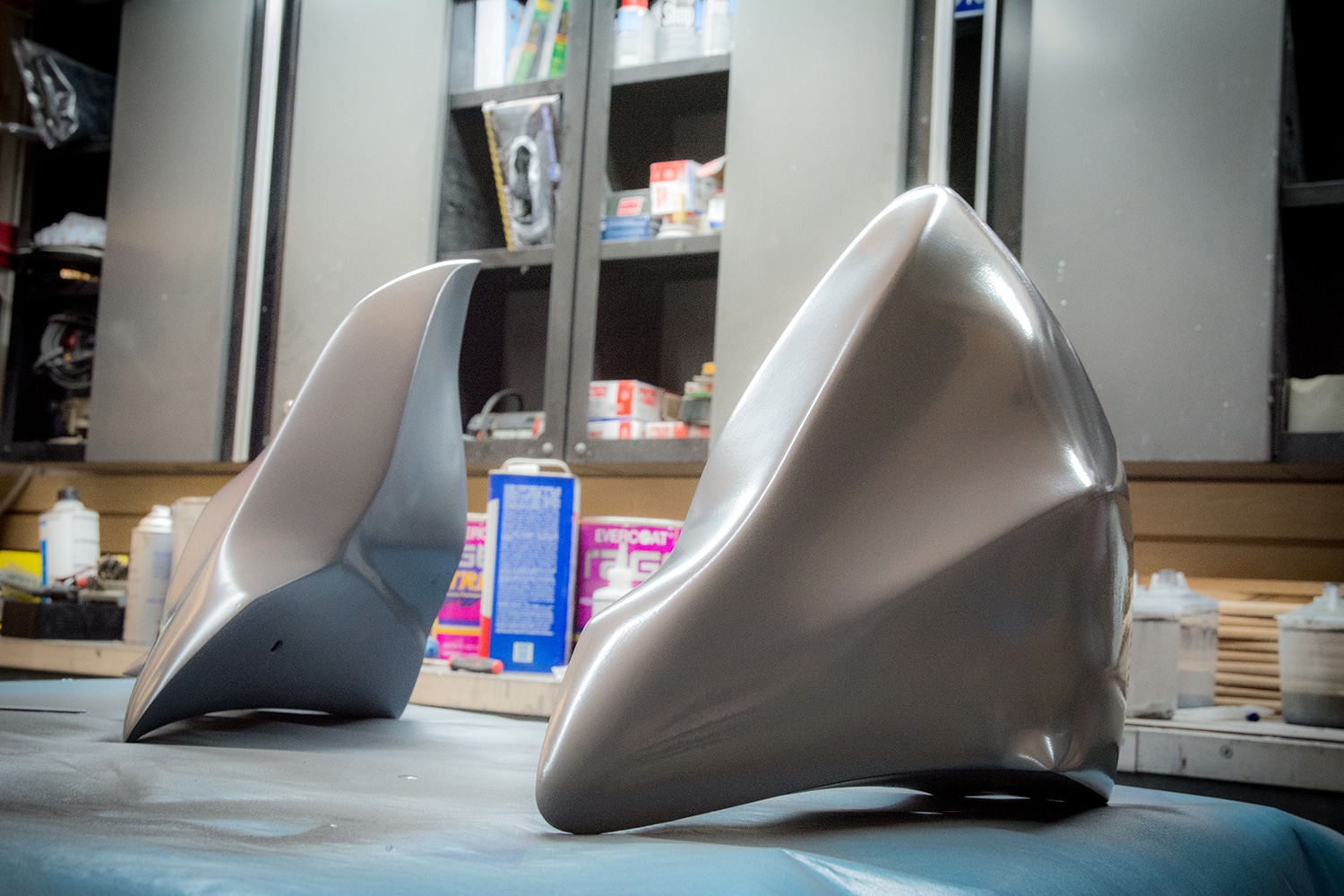

“This job may be the biggest challenge I have taken on to date. This customer was familiar with the JL SlamPak pods that are made for the Can Am RS. His bike was the ST, so there was nothing in production for them. I told him if I made something, it would be quite expensive because I have to essentially make plugs, then molds so I can make the final part of 100% fiberglass. I told him we would put some grilles on the speakers that way they look a little more subtle on the bike. So I got right to it. I had to hand lay fiberglass on each front fearing on the bike, then make the skeleton out of ABS to lay out the shape of the pods. The lines flowed nicely into the hood and side ferrings of the bike. Once I had the shape created, I removed them from the bike and filled in the excess with 2 part foam. I then shaped each pod to mirror the other. Once that was complete, I had to take a fiberglass mold of the inner and outer side of each pod. Once I had that, I finally make my finished pod. I laid fiberglass into each mold, creating the final inner and outer layer of my pod.

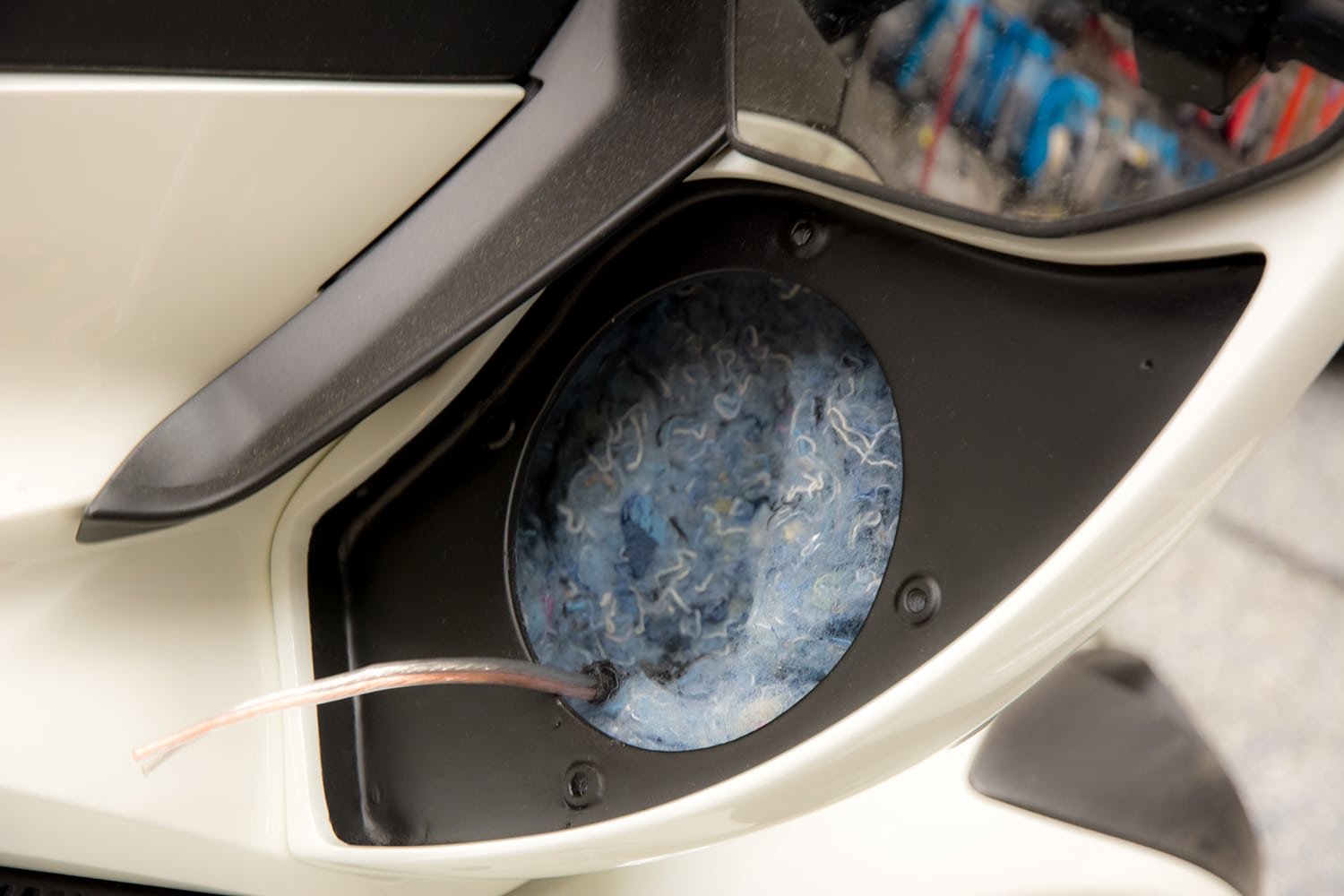

I then laid 7 layers of fiberglass to make the speaker baffle for my pod. Once those were dry and cut, I molded them into the opening of the pod. Once all the body work was done, I shot the pods with a layer of poly primer followed by 2k primer and 3 stage pearl paint. I use m5 nutserts to bolt the speaker to the fiberglass baffle and two 1/4-20 nutserts to bolt the pod to the ferring. I then finished off each pod with an acrylic trim with a press grill to protect the speakers. The trim was removable with 2 insert magnets under each grille.

I installed the tweeters to my component set where the only set of speakers resided from the factory which was in the 4” location under the grilles by the gauge cluster.

Under the hood I fabricated a stack layer enclosure using birch to house my 8” focal flax subwoofer. The enclosure bolted to the frame using a m8 bolt. On top of the enclosure I fabricated a trim panel using PVC to display the Mosconi 100.4 DSP amplifier and subwoofer. The grill was bent at a 45 to continue the slope of the trim panel. The system ran off the Mosconi using two different presets that automatically switched when the customer used the factory radio and bluetooth using AMAS.

This gave the customer a full, integrated, solution to give him the best equipment in space that primary did not exist from the start of the job. ”